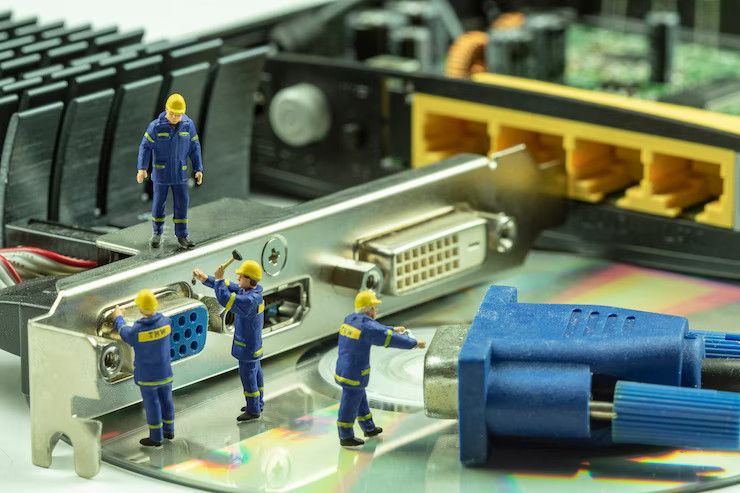

Operation maintenance

Operational & Maintenance Services – A best guide to achieve operational Efficiency

EnergiSpeak's Effective Operations and Maintenance (EO&M) stands out as a highly cost-effective approach to ensuring reliability, safety, and energy efficiency. In industry, insufficient maintenance of energy-using systems is a major contributor to energy waste. Significant energy losses arise from issues such as steam, water, and air leaks, uninsulated lines, malfunctioning controls, and other maintenance-related shortcomings. Robust maintenance practices not only generate substantial energy savings but should also be viewed as a valuable resource. Additionally, enhancements to facility maintenance programs often yield immediate benefits at a reasonable cost.

EO&M encompasses decisions and actions related to the control and upkeep of property and equipment. These activities include, but are not limited to:

-

Actions concentrating on scheduling, procedures, and work/systems control and optimization.

-

Execution of routine, preventive, predictive, scheduled, and unscheduled actions aimed at preventing equipment failure or decline, with the objective of enhancing efficiency, reliability, and safety.

Operational Efficiency represents a life-cycle, cost-effective combination of preventive, predictive, and reliability-centered maintenance technologies. This is coupled with equipment calibration, tracking, and computerized maintenance management capabilities, all geared towards ensuring reliability, safety, occupant comfort, and system efficiency.

EnergiSpeak's EO&M serves as a computerized maintenance management system with an Operations & Management software module that supports O&M activities. These systems automate numerous logistical functions performed by maintenance staff and management, offering advantages over manual maintenance tracking systems. Depending on the system's complexity, typical functions may include:

- Work order generation, prioritization, and tracking by equipment/component.

- Historical tracking of all work orders sortable by equipment, date, person responding, etc.

- Tracking of scheduled and unscheduled maintenance activities.

- Storage of maintenance procedures, warranty information, and technical documentation by component.

- Real-time reports of ongoing work activity.

- Calendar- or run-time-based preventive maintenance work order generation.

- Capital and labor cost tracking by component, along with time metrics for closing work orders.

- Complete parts and materials inventory control with automated reorder capability.

- PDA interface for streamlined input and work order generation.

- Outside service call/dispatch capabilities.

The primary advantage of EnergiSpeak's EO&M lies in eliminating paperwork and manual tracking activities, enhancing the productivity of building staff. It's important to note that the EO&M's functionality lies in collecting and storing information in an easily retrievable format. While it doesn't make decisions, it equips the O&M manager with the best information to enhance a facility's operational efficiency.

Key benefits of EnergiSpeak's EO&M includes

- Early detection of impending problems, reducing failures and customer complaints.

- Higher levels of planned maintenance activities for efficient staff resource utilization.

- Improved inventory control, leading to better spare parts forecasting and minimized shortages.

- Maintenance of optimal equipment performance, reducing downtime and extending equipment life.